The How of Cow: Processing & Weights Explained

Notice: This is a guide only and all information within should be considered as an approximation of weights and storage recommendations.

So, you've been thinking about filling your freezer with a full or half side of beef but haven’t made the move forward yet, well… that’s understandable. Many folks may wonder, “How much meat will I actually be getting back, and do I have enough room to store it all?”

Here are some quick bits of info that may help you make that decision and clear up any confusion.

The 3 Weights

There are three weights that are referred to when selling meat in bulk. The live weight, the hanging weight, and the packaged weight.

1) Live weight is plainly just the weight of the cow when it’s alive, or “on the hoof.” The weight of the animal when it arrives to the butcher.

2) Hanging weight or carcass weight is the weight of the animal after it has been killed, with all it’s blood drained, it’s hide, head, feet, and offal removed. This is the weight that provides the most consistent measuring of a carcass before it is further processed into cuts. The hanging weight is also what the butcher uses as the basis to charge us, the producer, for cutting and packaging. This is the weight that buyers and sellers use to calculate cost.

3) Packaged weight or take home weight is how much the customer will take home and store in their freezer(s) - this is the weight of the animal after it has aged, been de-boned, and packaged.

Butchering and Weight Loss

Throughout the butchering process, much of the live weight of the animal is lost through the removal of bones and water evaporation. This is the typical assumption we make when considering the processing of a grass-finished beef carcass:

Hanging Weight is 51-60% of Live Weight

Packaged Weight is 51-60% of Hanging Weight.

Example: A 1000 pound animal may weigh 510 - 600 pounds after initial butchering (hanging weight).

Water loss occurs during the dry aging process that allows the beef to tenderize. Every cow hangs under refrigeration for dry aging at the processor for a minimum of 14 days.

The other place you lose weight during the butchering process is from cutting the meat off of the bones. This is one reason why predicting the exact packaged weight is impossible. It’s important to mention that a lower packaged weight doesn’t mean you are receiving less meat, but rather, you are receiving less weight in bones. For example, the more boneless cuts the customer requests, the less the packaged weight will be.

We aim for our pastured beef to weigh 1,200 pounds at finishing weight to insure the hanging weight hovers around 650 pounds. This is dependent mostly on scheduling with the butcher. Our beef are grass-finished so we don’t “fatten” them up on corn and grain to a desired weight before processing. We estimate weight gain on pasture and do our diligence to schedule with the butcher appropriately. Sometimes the butcher doesn’t have an opening when we exactly want it, and the animal will end up going in a little under or a little over 1,200lbs.

The Cost

When purchasing pasture-raised beef in bulk, directly from small ranchers like us, you save money. You’re paying for the hanging weight of the animal in bulk, vs the cost of purchasing by individual steak cuts and ground by the pound.

The customer, aka farm supporter, pays a deposit on the beef cattle to be processed, which is an approximation of half the final cost. Based on hanging weight.

We offer whole and half beef shares, periodically, and charge by hanging weight (see definition above).

Current cost: As of May/June of 2025 - Price is $9.09/lb Hanging Weight

Basing off an average of 650lbs, whole beef would be $5,908.05 (remember the animal could hang above and below 650lbs)

Deposit Amount:

Half Beef - $1,500

Whole Beef - $3,000

The deposit amount above would be deducted from the final total based on hanging weight and would be due when picked up or delivered.

Please call or email us if you have questions about the ordering beef in bulk! Here also is a link to the USDA Grass Fed Beef Report that is updated monthly. See: Direct-to-consumer> Carcass purchase size.Hanging weight for a whole beef is often around 650lbs. Cut and packaged you receive approximately 60% of the hanging weight, so if ordering a whole beef you could expect approximately 300-400 lbs of meat and bones.

Customized Cuts

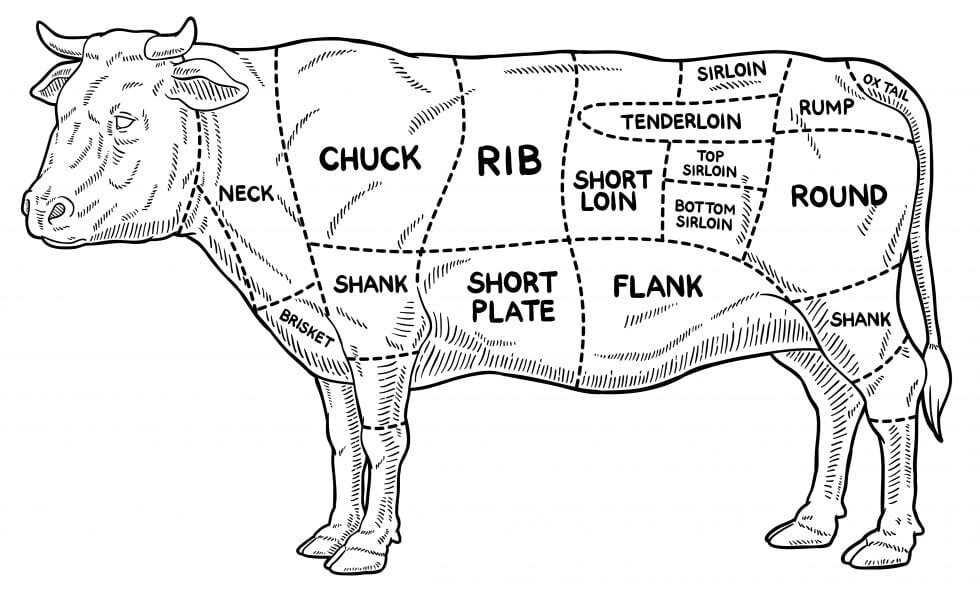

Below is a list of cuts you may expect to see when receiving a bulk order of a whole beef from Flat Rock Creek Ranch:

Brisket, T-Bones, Ribeyes, Ribs, NY Strips, Tenderloin steak (think filet mignon), Sirloin, Flank Steak, Rump Roasts, Pikes Peak Roasts, Fajita Meat, Ground Meat, Ground Primal, Soup Bones, Beef Bones, Heart, Liver.

Storage

You’ve ordered your bulk beef, it’s been processed, and now it’s ready for pick up. Because you’ll be receiving your whole or half share of beef all at the same time, you’ll need to make sure you have enough freezer space to accommodate your order.

For us at the ranch, we only temporarily store the frozen packaged beef in our freezers until the customer comes to pick up their order (we deliver locally, too). We use one upright, 21 cubic sq ft freezer for each full beef that comes back to us from Harvest House, our USDA certified processor. A half beef share would require approximately 10 cubic sq ft for storing. Beef shares are returned to the customer shrink wrapped, frozen, labeled, and organized neatly in large folding cardboard boxes.

From the date of processing to the time the beef makes it back to our freezers, about 3-4 weeks will have passed. It is not uncommon for friends and family to “go in on” a whole share of beef and divide up the cost and storage, or even on a half beef share for that matter. Those 3-4 weeks often allow just enough time to figure out where and how you’ll store all the delicious pasture-raised beef after you reserve it. It’s comforting to know you’ll have beef for many months to come.

We hope that you find this guide helpful, and if you find yourself still with some questions, please, let us know!

Cutlets, T-Bones, and Loins… oh my!

Bring home hundreds of pounds of 100% grass-finished beef to stock your freezer. Offered periodically. Join our mailing list to find out first when we will be offering our beef as whole or halved.